The Idaho Transportation Department is pausing efforts to install a new containment system to capture any future fluids that may be released from heavy equipment that fell into Lake Coeur d’Alene near Higgens Point decades ago.

In February the department had hired a specialized contractor to design a new containment system. To design the system, ITD deployed divers underwater and initiated several types of imaging to determine the precise location of the equipment.

“We weren’t able to identify the exact location of the dozer to the point we would be able to place the new system,” Emergency Response Coordinator Chris Williams said. “Due to poor visibility under 90 feet of water, the historic landslide that buried the equipment, and the presence of heavy metals that make imaging ineffective, at this time we have decided to put our plans on hold.”

The equipment has not leaked fluids since December. After Memorial Day, ITD removed absorbent booms on the lake’s surface.

“With more boaters out on the water, maintaining these booms was not feasible or cost-effective,” Williams said.

ITD is working with the Idaho Department of Environmental Quality to determine next steps and implement a monitoring program.

New plans underway for cleanup of leaking dozer in Lake Coeur d’Alene

February 24, 2023

The Idaho Transportation Department has hired a contractor to design and build a new containment system to capture leaking petroleum products from a dozer that fell into Lake Coeur d’Alene during the construction of I-90 decades ago.

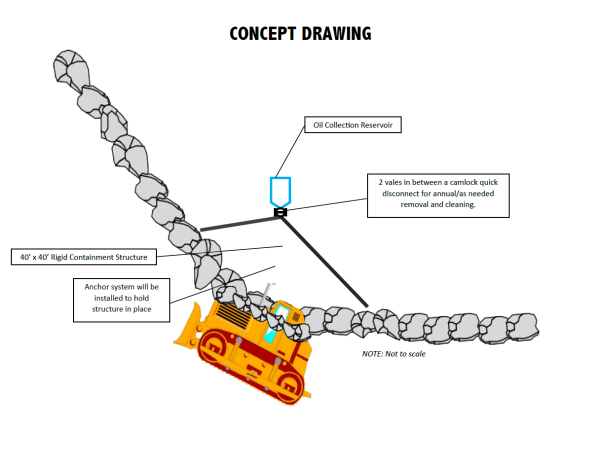

Associated Underwater Services out of Spokane is now drawing plans for a stainless steel hood that will encase the dozer, which is buried in rock and under about 90 feet of water, to prevent diesel and other fluids from contaminating the lake.

Once designed the hood will be built on the shore of the lake and could be in place as early as June. In the meantime, ITD will monitor the site and leave booms in the water to absorb any leaks.

“The hood will capture any leaks and is expected to be forty feet long by forty feet wide,” Emergency Response Coordinator Chris Williams said. “That’s a lot of stainless steel, and getting our hands on that material will be a challenge.”

The hood is similar to previous containment systems implemented since the dozer, as well as a scraper, fell into the lake in 1990. Earlier systems also used protective membranes to funnel any escaping fluids to a device where it could be emptied and replaced.

The latest leak was noticed in December and likely a result of a boat anchor disturbing the protective membrane and allowing diesel to be released to the surface. Both membranes will be removed, and the hood will be built large enough to completely cover the buried the dozer. Fluids will be trapped in the hood, which will have a containment vessel to monitor and empty when needed.

“We are committed to protecting the lake, which likely include several more years of monitoring and maintaining the hood,” Williams said.

Other options like removal of the equipment were considered with partner agencies like the Idaho Department of Environmental Quality but dismissed due to the risk of affecting the rockslide area and the potential harm to staff and the environment.

Diesel leaking from dozer at the bottom of Lake Coeur d’Alene

December 27, 2022

During the construction of I-90, two pieces of equipment fell into Lake CDA near Higgens Point and were unable to be recovered.

Contractor Scarsella Brothers, Inc., was placing fill in the lake in May 1990 to provide a base for an interchange at Higgens Point when the ground unexpectedly gave away, dumping a Caterpillar 631 scraper and a D-9 dozer and their operators into the water.

Both operators survived, but the dozer and scraper were barely visible and under about 90 feet of water.

ITD, the Idaho Department of Environmental Quality and several other agencies considered next steps. The tank of the scraper was able to be drained due to how it landed, but the dozer was inaccessible. State and federal agencies agreed that retrieval methods were too risky—both in terms of risk to personnel and to the stability of the slope underwater—and decided to abandon the equipment.

The proposed interchange was cancelled and replaced with plans for a parking lot.

THE FIRST LEAK

The dozer did not appear to leak product until 2000, when a sheen was noticed and determined to be coming from the dozer.

Booms were put in place to contain and capture the product, and ITD hired an engineering firm, CH2M Hill, to analyze field conditions and recommend options to resolve the current leak and capture future releases.

Seven options were put forth and evaluated for effectiveness, feasibility and cost. Both options to remove either the fuel tank from the dozer or the entire machine were rejected due to danger to personnel, the possibility of triggering a slide or the risk of releasing more product through recovery efforts.

ITD and DEQ opted for subsurface containment and collection. In 2001 a specially designed stainless steel hood was built and installed to cover the release site and capture any releases in a canister that could be emptied safely by divers. In 2002 a protective membrane was added to partially cover the dozer and further funnel product into the hood.

Eventually with no product coming to the surface, the booms were removed.

THE SECOND LEAK

Another leak in 2010 led to the removal of the hood, which needed maintenance, and was replaced with a larger membrane and a simple catchment system to receive and absorb any product.

That system remained in place, with no leaks detected until 2022.

CURRENT EFFORTS

Late December 7, ITD was notified of product coming to the surface in the general vicinity of the relic equipment.

The department placed floating booms to both contain the suspected diesel leak from the dozer and protect the shoreline. Dives determined that the equipment was still buried but that the older, first protective membrane had been disturbed, likely after being caught by a boat anchor. The other membrane looked to be intact.

ITD is again working with DEQ to pursue a specialized contractor to implement a quick and minimally invasive solution to capture and contain the leak. Once contained future, more permanent projects may be considered and developed.